|

| SELECTIVE SYSTEMS |

|

The basic components are: Frames, Beams, Wire decks, Cross bar, etc.

100% Product selectivity

Requires two access lanes to products for every rack line

It usually takes two or three pallets for each pair of frame and beams

|

| "DOUBLE DEEP" SELECTIVE SYSTEMS |

|

The basic components are: Frames,Step Beams Dividers, Wire decks, Cross bar, etc.

Consider that this system requires a special floors of the type of forklifts used (double deep)

At least 30% space optimization

Consider the purchase of a double deep forklift

Consider that the WMS should be configured for double slot

Low inicial cost, high productivity, good selection and less equipment damage.

|

|

| PUSH BACK SYSTEM |

It combines the advantages of the auto transport of a pallet flow rack and the space saver of the drive in.

High density

The pallet makes the trip in the same trolley

Requires only one lane to function

Our system allows a design of 6 pallets deep to be stored per level

Last in - First out system

|

|

| KANBAN SYSTEM |

|

Space maximization in the use of loose boxes

Compatible with any type of rack

High flexibility and capacity in terms of the size of the boxes

Depth size to choose: between 43 and 96

|

| PICKING - SHELVES |

Optimal solution for different article types and split turnovers.

Valid for storing large and heavy items

Capacity Range per level: 450 kgs 1200 kgs

Optional wood shelves or galvanized metal panels

Easy to assemble

This system allows the height of the warehouse to be maximized by installing gangways with access to higher levels.

|

|

| SLOTTED ANGLE SHELVING |

|

Simple and economic system for a wide range of applications

Capacity Range per level: 100-120 kgs

Common Heights: 1.82 and 2.13 mts

Standard shelves: ( 90cm or 1mt ) x 30 , 40 , 50 or 60 cms

Components: shelves, slotted angles, screws

Adaptable to all storage needs

Excellent versatility

Easy to assemble

|

| MEZZANINE |

Could be the most economic solution to increase space in the warehouse by eliminating the need to rent or build a new industrial plant.

|

Mezzanine parts include: Columns, Primary Beams, Secondary Beams, Floors, Steps, Rails, Mounting plates.

Optional floor: Wood, B-Deck wood, Metal bar grating in various versions

Clean, fast and easy installation

Multiplies surfaces space in industrial premises

Adaptable to the specific needs of the client due to the great variety of sizes available, types of floor, construction systems, etc.

Available to design columns up to 26 X 26

Loads of up to 300 lbs/square foot

|

|

| MIXED SYSTEM |

|

Designed to adapt with various solutions, mezzanines, shelves, racks, cabinets, work stations and much more.

Flexible modular systems that evolve with the future growth of your warehouse

Common Market: Automotive, hospital, government, manufacturing, and military warehouses

Versatility to manage any type of product

Load capacity: 250 kg 886 kgs

|

| SPECIAL APPLICATIONS |

Roll out shelves:

Designed to carry up to 3000 lbs per shelve

Ideal for moldings and tools

Easy access to the product

|

|

|

Application with metal rolls

Designed considering size and weght of coil

Capacity up to 3900 kgs per coil

Suggested depth sizes of frames: 32,36,42,44,48

Usually use one coil per pair of boards

|

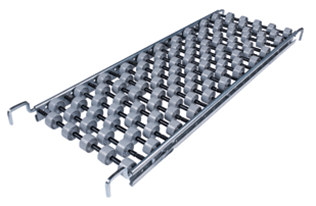

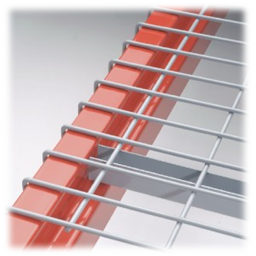

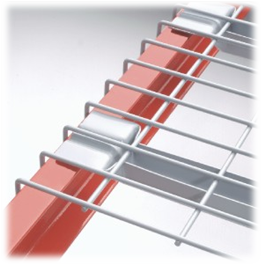

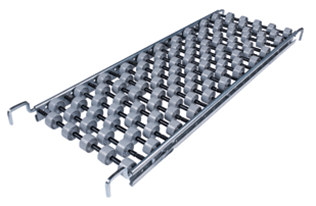

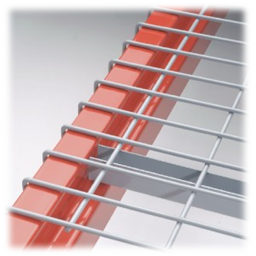

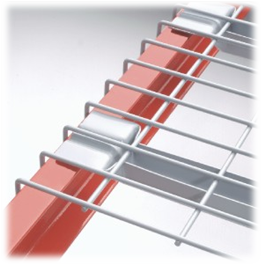

| ACCESSORIES: WIRE DECKING |

|

|

|

Easy installation

High visibility for inventory and inspection

Clean and safe for pallet handling

|

Customized and standard measures for more capacities

Compiles with all fire and hazard codes

|

| ACCESSORIES: RACK BACK |

Ideal for installing in limited walking lanes

Modular panel system of 4' and 5' wide

All panels are welded together and can have special measures

Screw directly to the rack frame

The panel can be next to the frame or separated from it up to 12

|

|

| ACCESSORIES: BARRIERS |

|

Ideal for protecting machine areas, office or rack areas from accidents involved with forklifts

Easy installation

Available in single or double rails

Standard rail measures: 10', 8', 6', 4' 2'

|

| ACCESSORIES: WIRE DIVIDERS |

Ideal for protecting equipment, storage and personnel areas

Modular system with various access and security options

Standard height: 6' 2 but can be customized to fit client needs

Most common width: 4' and 5'

|

|

| ACCESSORIES: RACK SENTRY |

|

Designed to absorb and better distribute the force of impacts

Easy installation

No tools needed for installation

Easy to clean

Compatible with the majority of racks

|

| RETURNABLE PACKIGN AND PACKING SYSTEMS |

These systems generate added value in material handling performance and cuts operation costs. |

Superior protection of products

Improved material handling

Better ergonomics

Optimization of space

Reduces the cost of labor

Transportation cost reduction

Less waste

Cleaner environment

|

|

|